The company has perfect technology research and development system, professional research and development team, strong research and development ability, multi-level research and development innovation platform, continuous research and development investment guarantee, and constantly consolidating the research and development results.

The company's technology research and development system is research center oriented, and supplemented by technology center. The R&D center is mainly engaged in the research and development of grinding system technology and equipment, mineral evaluation and process investigation, and the technical center is mainly engaged in the transformation of scientific and technological achievements, product design, sales, manufacturing and delivery. The company has cooperated with famous universities at home and abroad to set up academician (expert) innovation workstations and doctoral innovation practice bases which expands to suppliers and users, and forms an industry-university-research integration technology innovation system that integrates technology research and development, scientific research, trial production and promotion.

With good development prospects, excellent corporate culture, rich incentive mechanism, Leejun constantly attracts outstanding talents in the field of grinding technology which ensures the new power and vitality with the company’s development. Now there are more than 80 R&D staffs in each field , of which more than 30 are senior technical talent. Core technical staffs with doctoral and master’s degree are graduated from Sichuan University, Northeastern University, Harbin Industrial University, Wuhan University of Technology, University of Electronic Science and Technology, Southwest Jiaotong University, China University of Petroleum, Chongqing university and other domestic famous universities. At the same time, the company has developed a series of incentive systems to ensure the highest income level of R&D personnel in the company and effectively encourage R&D personnel to carry out technological innovation.

Director shall assume overall responsibility for R&D center and technical center , and which is supervised by technical committee. The R&D center consists of mechanical department, building materials department , mining technology department, electrical automation department, and material systems department, as well as mining materials comprehensive laboratory and ore processing analysis laboratory, Leejun also established a construction area of about 2500 square meters of research and development base, and cooperates with well-known research institutions at home and abroad to set up academician (experts) workstation, and postdoctoral workstation. Thus, it has established a multi-level platform of technological innovation and formed a professional advantage of technological research and development.

The company introduced the industry's first-class design software which can conduct product design, finite element analysis, three-dimensional design simulation, and established an efficient design system. The company has spent a lot of money to build the analysis and test center and a number of fully automatic control industrial test systems, introduced the advanced inspection and test laboratory equipment at home and abroad, and established an effective analysis and test verification system. New product development includes a closed-loop management system from demand investigation, scheme and technical design review, trial production, user on-site verification and design improvement.

The company attaches great importance to research and development investment, and continuous investing R&D funds in new products, new technologies, new materials and new processes. With the continuous expansion of business, the company will continue to increase the construction of research and development institutions and investment in research and development funds to improve the company's technical level and core competitiveness.

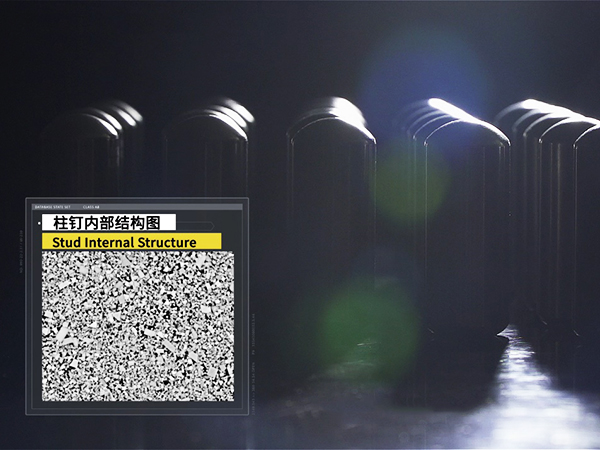

The company's scientific research strength has been highly praised and recognized by the industry. The company owns nearly 200 patents of mine grinding, cement raw material, etc., and many patents and technical achievements have been awarded by the state, Sichuan province and Chengdu city. The company has passed ISO9001 quality management system, ISO14001 environmental management system and CE certification. Company technology center is identified by Sichuan province in 2006, the company research and development production of roller press equipment and grinding system has been rated as "China Famous Brand Product", and was included in the "National Energy Conservation Technology Promotion Project", the company and the technical personnel has been awarded “standardization advanced collective", "standardization advanced worker ".The company participated in drafting "Roller Press for Cement Industry" (JC/T 845-2011), JC/ t2104-2012 "Wear-resisting Surfacing Welding General Technical Conditions for Cement Industry", "Roller Press for Cement Industry", "Technical Requirements for New Dry Cement Production Equipment" and other standards. In the cement building materials industry, the company takes the lead in applying roller press to cement raw material grinding system successfully. In the metallurgical and mining industry, the company has successfully developed and manufactured the replaceable roller surface of HPGR with independent intellectual property rights. Its unique function of rapid stud repair and side end protection technology has laid a solid foundation for the application of HPGR in the field of mineral processing, and it is at the forefront of HPGR technology development.

Product Development Milestone:

In 2000, the company developed the first generation of products -- DDX multi-point feeding multi-point unloading tray conveyor and improved O-sepa separator, ZX combined separator, coal mill dynamic separator.

In 2001, the company developed cement roller press pre-grinding system.

In 2001, the company's first separator entered the international market.

In 2002, the company developed the cement roller press combined grinding system.

In 2003, the first CLF140 series roller press developed by the company was put under operation in Jiangsu province.

In 2004, the first CLF170 series roller press developed by the company was put under operation in Shandong province.

In 2005, the company's first roller press entered the international market.

In 2006, the first CLF180 series roller press developed by the company was put under operation in Shanxi province.

In 2006, the first compound roller (CLF14065) developed by the company was put under operation.

In 2007, the company developed the first roller press cement raw material process system and was put under operation.

In 2008, the "Cement Raw Material Finished Grinding System" developed by the company won the national invention patent, and was announced by the National Development and Reform Commission No. 36 as "The first Batch of National Key Energy-saving Technology Promotion Project".

In 2009, the CLM HPGR developed by the company was put under operation in the iron ore field, opening a new chapter in the metallurgical mining industry.

In 2009, the first stud roller developed by the company (CLM20080) was put under operation.

In 2009, the first CLF200160 super-large roller press developed by the company was put under operation

In 2012, the company participated in drafting JC/ t845-2011 "Roller Press for Cement Industry" building materials industry standard.

In 2013, the CLM HPGR developed by the company was put under operation in the field of manganese ore and bauxite.

In 2014, the first CLM260160 super-large HPGR developed by the company was put under operation.

In 2016, the CLM HPGR developed by the company was put under operation in the field of ceramics and minerals.

In 2018, the company participated in drafting GB/T 35150.1-2017 “Technical Requirements for Complete Sets of Equipment for New-style Dry Type Cement Production Part 1: Raw Material Preparation System”; Participated in drafting GB/T 35168-2017 “Roller Press for Cement Industry”.

……

-

Large Roller Press for Magnetite

-

2013 Advanced Collective in Standardization of Building Materials

-

High-tech Enterprise Certificate

-

Executive Members of Building Materials Association

-

The Torch Project

-

Science and Technology Innovation Achievement Award

-

Second Prize of Science and Technology Progress Award

-

Cement Machinery Top 20

-

Sichuan Machinery Industry Top 50

-

Sichuan Enterprise Technology Center

-

Demonstration Project of Major Scientific and Technological Achievements Transformation Project in Sichuan Province

-

Industry Credit AAA

-

Leading Enterprise of China Building Materials Association