01

02

no1.

System solution

In every corner of the world, we will continue to meet individual customer needs and new technical challenges. With a team of skilled engineers, strong technical experience, and a sound management system, we have consistent professionalism and a service attitude of excellence. Leejun's complete solution for grinding system not only tailors the needs of users, but also achieves a harmonious and win-win situation in the coexistence of people and nature.

no2.

CLF series roller press

CLF series roller press is widely applied in the field of cement and building materials. It is grinding equipment designed based on the principle of material bed comminution. It is mainly composed of frame, roller system, hydraulic system, feeding device, control system and transmission system. The roller system is divided into a floating roller system and a fixed roller system. The two roller systems are rotated at a relatively slow speed, and the floating roller assembly can move horizontally on the frame rail by the pressure of the hydraulic cylinder and grind the materials continuously fed into the gap between the two rollers. The materials are crushed and pressed into a cake to fall outside the machine.

Parameters:

-

1400-2000Roller diameter/mm

-

300-1800Roller width/mm

no3.

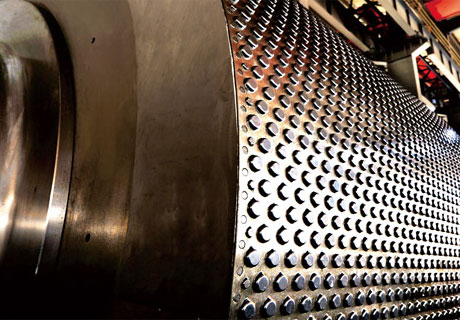

CLM series HPGR

CLM series HPGR is widely applied in metallurgical mines and chemical industry etc. It is a kind of grinding equipment designed based on the principle of material bed communition, mainly consisting of frame, roller assemblies, hydraulic system, feed gate, control system, transmission system and other components. The roller assemblies are divided into a floating roller assembly and a fixed roller assembly. The two roller assemblies are rotated at a relatively slow speed, and the floating roller assembly can move horizontally on the frame rail by the pressure of the hydraulic cylinder and grind the materials continuously fed into the gap between the two rollers. The materials are crushed and pressed into a cake to fall outside the machine.

Parameters:

-

250-3000Roller diameter/mm

-

100-2000Roller width/mm

no4.

EPC contracting

Since its establishment in 1999, Leejun has been deeply involved in the research and application of material grinding and separation technology, and is an industry expert with over one thousands production line application performance and core technology, creating value for customers in nearly 40 countries and regions around the world.

no5.

Spare parts

The stud roller (Invention Patent No. ZL201110263519.5) is a new generation of roller surface independently developed by Leejun. It consists of forged shaft core, special alloy roller sleeve and wear-resistant hard alloy stud. Its characteristics are: the overall wear resistance is greatly improved, the material carrying capacity is stronger, the performance is more stable, and the production and efficiency are improved.